This article aims to highlight the clinical, organizational, and environmental benefits of using custom packs for local regional Anaesthesia (LRA), with a focus on promoting a sustainable and efficient approach. Specifically, this analysis will show:

- How custom packs can reduce packaging waste by several tons per year at a single hospital.

- Evidence of time savings of nearly six minutes per procedure, directly improving operating room efficiency.

The Hidden Costs of Disorganization in the Operating Room

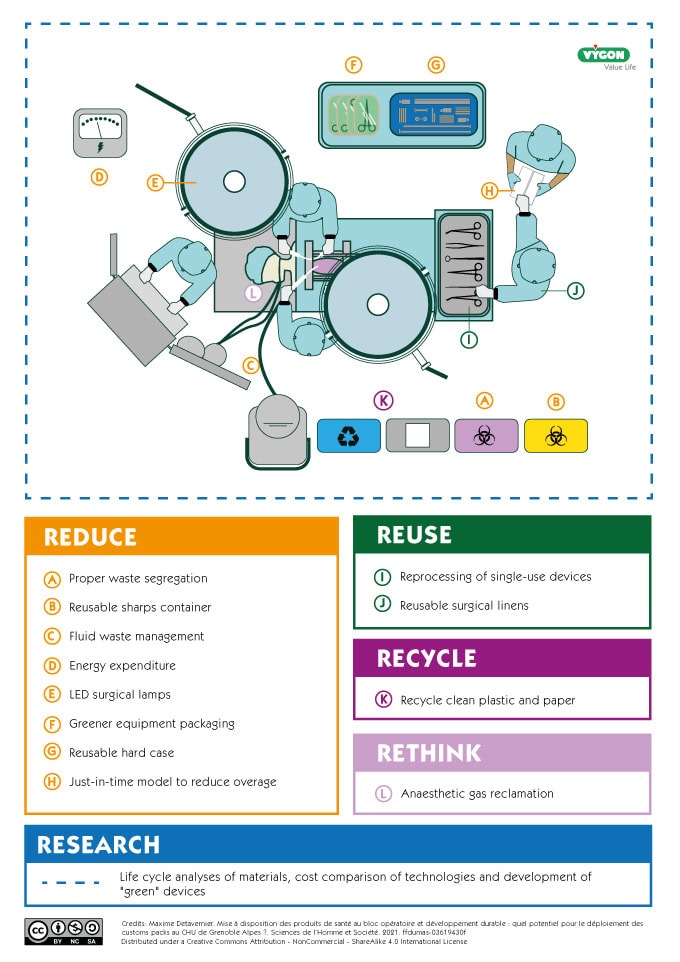

In the global push for sustainability, the healthcare sector is under intense scrutiny, as it accounts for 4.4% of global net emissions.

Local-regional anaesthesia and Sustainability: The Green Revolution in the Operating Room

A significant portion of this impact comes from the operating room, not only from anaesthetic gases, but from a less obvious source: waste and inefficiency.

Traditional preparation for a medical procedure involves gathering dozens of individually packaged items: gloves, needles, syringes, drapes and more.

This approach generates a huge amount of plastic, cardboard and paper waste in each case.

The costs are not just environmental. This method has a direct impact on clinical efficiency and safety. When materials are gathered separately, the risk of a critical item missing increases significantly, which can lead to wasted time, increased stress in emergency situations and, most importantly, a greater risk to aseptic standards.

How can we streamline procedure preparation to make it faster, safer and more environmentally friendly? The answer lies in a simple concept: the custom pack.

A custom pack is a unique, sterile package containing all the devices needed for a specific procedure, manufactured on demand to suit the specific needs of a clinical team.

A Measurable Impact on Waste Reduction

The most immediate and quantifiable benefit of adopting custom packs is the reduction in packaging waste. By consolidating all the necessary components into a single sterile package, custom packs eliminate redundant layers of plastic and cardboard from individual items.

A success story is that of Grenoble University Hospital (France). The implementation of 44 different custom packs in 16 surgical specialities resulted in a reduction of 5.89 tonnes of packaging waste in a single year. This figure represents a direct and significant contribution to reducing the operating room’s carbon footprint.

Gaining time, efficiency and peace of mind

In addition to the environmental benefits, custom packs offer significant organizational improvements.

Several studies have shown that using a custom pack saves an average of 350 seconds, approximately six minutes per operation. Extrapolated to a hospital’s annual surgical volume, this translates into thousands of hours of staff time saved that can be reallocated to direct patient care.

This time saved has a direct effect on staff well-being. By optimizing workflows and ensuring that all the necessary equipment is present and correct, custom packs significantly reduce stress, especially in high-pressure emergency situations.

The logistical burden on support staff is also alleviated, simplifying inventory management, ordering and storage.

This optimized model not only increases efficiency, but also fosters a calmer, more controlled and predictable operating environment for the entire clinical team.

Minimizing Risk and Improving Asepsis

Any change in the operating room must be judged by its impact on patient safety. In this regard, custom packs offer their most important advantage.

By providing a complete, pre-verified set of equipment, they dramatically reduce the risk of human error. This built-in “checklist” function provides an essential layer of safety and standardization.

In addition, custom packs improve safety by reducing the risk of aseptic failure. Fewer individual packages mean fewer surfaces to handle, minimizing opportunities for contamination.

The “triple benefit” for a modern operating room.

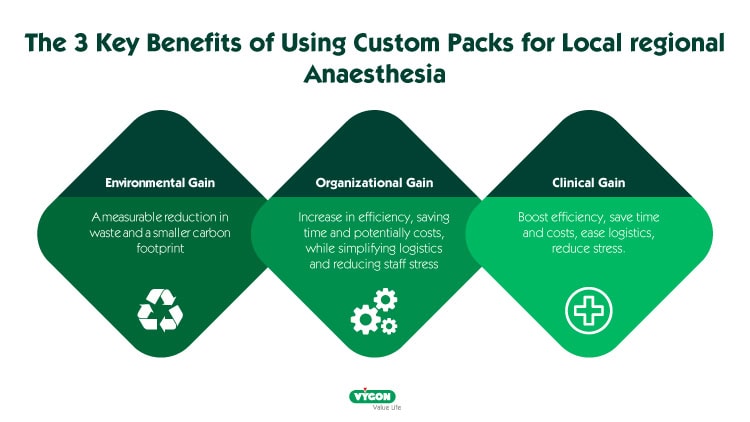

Adopting custom packs is much more than a simple product change; it is a strategic decision that offers a “triple win” for any modern healthcare institution.

- Environmental gain: A measurable reduction in waste and a smaller carbon footprint

- An Organizational Gain: A significant increase in efficiency, saving time and potentially costs, while simplifying logistics and reducing staff stress

A Clinical Gain: A higher level of safety by reducing errors and the risk of contamination, which contributes to improving patient outcomes and staff satisfaction

In an era where healthcare must be sustainable while staying efficient, and safe, the custom packs emerge as an indispensable tool. It demonstrates that it is possible to simultaneously optimize environmental, organizational, and clinical objectives, making it a smart and responsible investment for the future of surgery and anaesthesia.

Bibliography

- Peycelon, M. (2023). Mise à disposition des produits de santé au bloc opératoire et développement durable : quel potentiel pour le déploiement des customs packs au CHU de Grenoble Alpes ? [Thèse de doctorat, Université Grenoble Alpes]. DUMAS. https://dumas.ccsd.cnrs.fr/dumas-04087324v1

- Esposito C.D., Rocchi E., Folsi M.F. Introduction des custom packs dans le réseau hospitalier de la province de Lecco : projet, mise en œuvre et résultats. Forum. 2012;4:15–18. http://www.sssh.ch/uploads/media/f0412_esposito_F.pdf

- Thiel CL, Fiorin Carvalho R, Hess L, et al. Minimal Custom Pack Design and Wide-Awake Hand Surgery: Reducing Waste and Spending in the Orthopedic Operating Room. Hand N Y N. 2019;14(2):271-276. doi:10.1177_1558944717743595.pdf