Healthcare facilities are under increasing pressure to adopt sustainable practices without compromising patient safety or efficiency. Operating rooms, as high-resource environments, present a unique opportunity for impactful change.

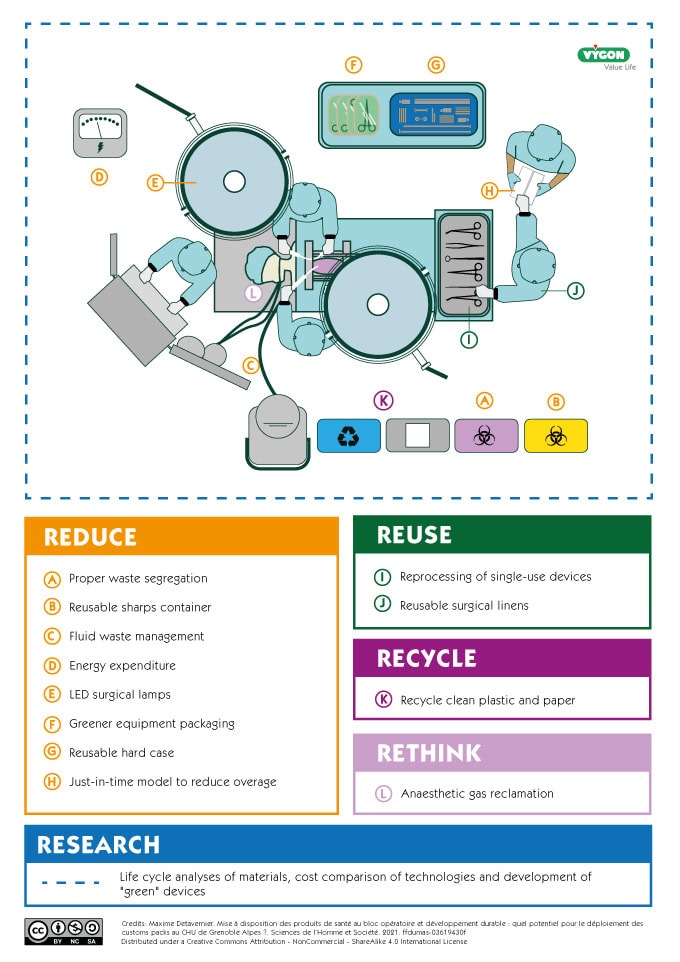

This infographic, “Areas for Making the Operating Room More Environmentally Friendly,” highlights actionable steps such as reducing packaging waste, reusing surgical materials, and recycling clean plastics and paper.

Download it now to explore how your hospital can contribute to a greener future while maintaining clinical excellence.